Product Classification

Ceramic aggregate plug-in rotary kiln

Ceramic sand rotary kiln: efficient calcination, promoting the production of green building materials

Learn more →Lime rotary kiln,Rotary Kiln for Rare Earth Processing wholesale

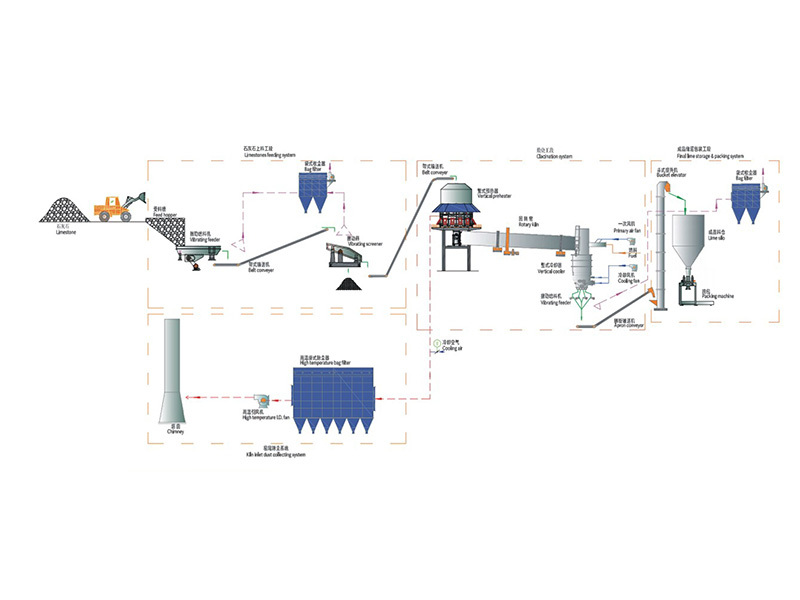

Lime rotary kiln is a kind of high-efficiency and energy-saving calcining equipment, which is widely used in the calcining process of limestone, dolomite, magnesite and other materials.

Learn more →Magnesium metal rotary kiln: efficient calcination, boosting magnesium metal production

Learn more →Reduced iron rotary kiln (sponge iron rotary kiln): efficient reduction, promoting green metallurgy

Learn more →The energy-saving lime rotary kiln has a stable operation structure and adopts a low-pressure-loss vertical preheater to effectively improve the preheating effect. The decomposition rate of the preheated limestone before entering the kiln can reach 30%. It has strong fuel adaptability and can use solid powder fuel, liquid fuel and gas fuel. The finished lime has high activity. This type of kiln is widely used in the national steel industry, chemical industry, etc.

Learn more →The rotary kiln consists of a cylinder, a transmission device, a support, a wheel support device, a kiln lining, a kiln tail seal, a kiln head cover and a fuel device. The kiln cylinder is a heated rotating part, made of high-quality carbon steel plate rolled and welded. The cylinder is supported on the support device through a wheel belt, and a mechanical or hydraulic wheel is provided on one or several gears of the support device to control the axial movement of the cylinder; the transmission device rotates the cylinder at the speed required by the process through the gear ring located in the middle of the cylinder; due to the need for installation and maintenance, larger kilns are equipped with auxiliary transmission devices that allow the kiln to rotate at a very low speed; in order to prevent cold air from entering and smoke and dust from overflowing from the cylinder, reliable kiln tail and kiln head sealing devices are provided at the feeding end and the discharging end of the cylinder.

Learn more →The externally heated rotary kiln is a new type of rotary kiln derived from the original single-tube rotary kiln in combination with the on-site production needs of customers. The heating methods are mainly gas heating and electric heating. The externally heated rotary kiln is suitable for the combustion, roasting, decomposition and drying of materials such as non-metallic minerals, metal minerals, medicines, foods, chemical products and agricultural products. It has the characteristics of compact structure, easy temperature control, simple equipment operation and convenient maintenance, high efficiency, energy saving and environmental protection.

Learn more →Cooler is a device for cooling calcined materials, belonging to the rotary drum type equipment. This product is widely used in cement building materials, nonferrous metallurgy, ferrous metallurgy, refractory materials, chemical raw materials, ceramics and papermaking, etc.; it has the characteristics of large production capacity, high degree of mechanization, simple maintenance and operation, etc.

Learn more →Rotary dryer is mainly used for drying and dehydrating various materials, and can also be used for drying compound fertilizers.

Learn more →Raw material mill is mainly used for grinding raw materials in cement plants. It is also suitable for grinding various ores and other grindable materials in metallurgy, chemical industry, power and other industrial and mining enterprises. It can be used for open flow grinding and also for circulating flow grinding composed of powder concentrator. Raw material mill has the characteristics of strong adaptability to materials, continuous production, large crushing ratio, easy speed adjustment and fineness of grinding products. Raw material mill can produce by dry method or wet method, and can also grind and dry at the same time.

Learn more →MQZ Energy-saving Bearing Edge Drive Ball Mill

The bearing-type edge drive ball mill is a technical transformation type. Compared with the traditional ball mill, it reduces the working current by 15%, reduces the starting current by 50%, and improves the problems of insufficient concentricity, unstable operation, high and low current, and serious wear of the hollow shaft according to the phenomenon of Babbitt alloy burning, shutdown, and production suspension. After the rolling bearing is adopted, the hollow shaft can continue to be used, saving 90% of lubricating oil, increasing the loading capacity by 20%, increasing the output by 15%, increasing the speed by 10%, and saving 20-30% of electricity per unit.

Learn more →Air-sweep mill is suitable for grinding coal powder. When coal powder is used as fuel in industrial furnaces and rotary kilns, the coal powder fineness is required to be more than 85% through a 200-mesh screen, and the moisture content is less than 2%. Air-sweep mill is an ideal coal powder processing equipment that can both grind and dry at the same time.

Learn more →