Rotary kiln

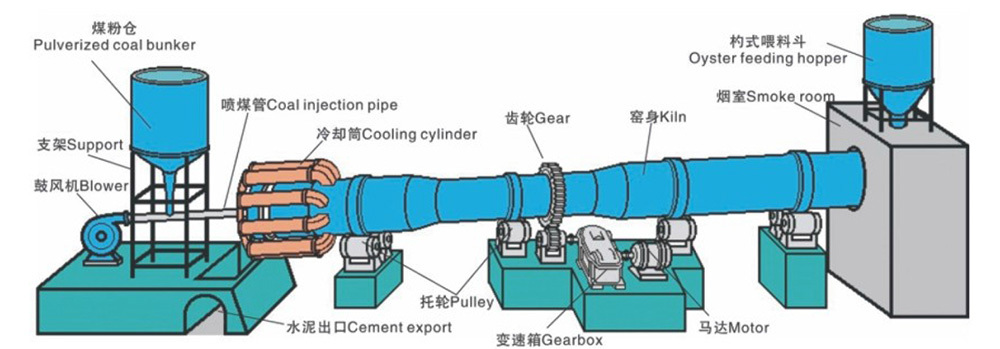

The rotary kiln consists of a cylinder, a transmission device, a support, a wheel support device, a kiln lining, a kiln tail seal, a kiln head cover and a fuel device. The kiln cylinder is a heated rotating part, made of high-quality carbon steel plate rolled and welded. The cylinder is supported on the support device through a wheel belt, and a mechanical or hydraulic wheel is provided on one or several gears of the support device to control the axial movement of the cylinder; the transmission device rotates the cylinder at the speed required by the process through the gear ring located in the middle of the cylinder; due to the need for installation and maintenance, larger kilns are equipped with auxiliary transmission devices that allow the kiln to rotate at a very low speed; in order to prevent cold air from entering and smoke and dust from overflowing from the cylinder, reliable kiln tail and kiln head sealing devices are provided at the feeding end and the discharging end of the cylinder.

Excellent production

Excellent production

After-sales worry-free

Quality Assurance

Product Classification:

Rotary kiln

WhatsApp:+86-15038279844

Product Introduction

The rotary kiln consists of a cylinder, a transmission device, a support, a wheel support device, a kiln lining, a kiln tail seal, a kiln head cover and a fuel device. The kiln cylinder is a heated rotating part, made of high-quality carbon steel plate rolled and welded. The cylinder is supported on the support device through a wheel belt, and a mechanical or hydraulic wheel is provided on one or several gears of the support device to control the axial movement of the cylinder; the transmission device rotates the cylinder at the speed required by the process through the gear ring located in the middle of the cylinder; due to the need for installation and maintenance, larger kilns are equipped with auxiliary transmission devices that rotate the kiln at a very low speed; in order to prevent cold air from entering and smoke and dust from overflowing from the cylinder, reliable kiln tail and kiln head sealing devices are provided at the feeding end and the discharging end of the cylinder.

Product Features

1. Support device: The main shaft structure is adopted, equipped with automatic temperature measurement device and electric heating device, and flow support is available for selection.

2. Wheel stop device: It is divided into mechanical wheel and hydraulic thrust wheel stop. The hydraulic wheel stop device is equipped with a hydraulic control system.

3. Transmission device: It is equipped with single transmission or double transmission. The speed regulating motor DC motor or variable frequency speed regulating motor controls the speed, which is reliable in operation and energy-saving and efficient.

4. Cylinder wheel belt pad: The lower pad of the wheel belt has fixed, adjustable and floating pads, which has the characteristics of simple structure, convenient maintenance and replacement, and no damage to the cylinder body when disassembled and replaced.

5. Sealing device: There are various sealing forms to choose from according to the different designs of the kiln type. Cylinder compression end face seal, spring compression end face seal, heavy hammer graphite block seal, spring graphite block seal, fish scale labyrinth seal, axial labyrinth seal and the above-mentioned combination seal, etc., which are characterized by strong adaptability to the movement and swing of the cylinder body and good sealing effect.

6. Dense hood: fixed and movable

Main technical parameters of rotary kiln

| Serial number | Specification | Yield(t/h) | Speed(rpm) | Number of supports | Reducer | Electric Motor | Power (kw) |

Remark |

| Model | ||||||||

| 1 | φ1.6×32m | 2 | 0.58-2.85 | 3 | ZQ75-50 | YCT250-4A | 18.5 | |

| 2 | φ1.6/1.9×36m | 2.5-3 | 0.53-1.59 | 3 | ZQ110-7 | YCT250-4B | 22 | |

| 3 | φ1.9×39m | 3-3.4 | 0.53-1.59 | 3 | ZO125-7 | YCT315-4A | 37 | |

| 4 | φ2.2×45m | 4-5 | 0.214-1.64 | 3 | Host ZS125-5 Auxiliary ZQ40-40 |

Host YCT315-4B Auxiliar Y112M-4 |

45 4 |

|

| 5 | φ2.5×40m | 6.3 | 0.62-1.5 | 3 | Host ZS165-5 Auxiliar ZS50-1 |

Host YCT355-4A Auxiliar Y160M-6 |

55 7.5 |

Preheater kiln |

| 6 | φ2.5×50m | 5-6 | 0.62-1.5 | 3 | Host ZS165-5 Auxiliar ZS50-1 |

Host YCT355-4A Auxiliar Y160M-6 |

55 7.5 |

|

| 7 | φ2.5×55m | 5-6 | 0.62-1.5 | 3 | Host ZS165-5 Auxiliar ZS50-1 |

Host YCT355-4A Auxiliar Y160M-6 |

55 7.5 |

|

| 8 | φ2.7×42m | 13 | 0.6-23 | 3 | Host ZS145-3-1 Auxiliar ZL50-16-2 |

Host YCT355-4A Auxiliar XH195diesel |

55 11 |

Preheater kiln |

| 9 | φ2.7×44m | 13 | 0.74-2.21 | 3 | Host ZSY355-50-1 Auxiliar ZSY160-40-2 |

Host YCT355-4A Auxiliar XH195diesel |

55 11 |

Preheater kiln |

| 10 | φ2.8×42m | 14 | 0.5-2.503 | 3 | Host ZSY355-50-1 Auxiliar ZSY160-40-2 |

Host Z2-101TH Auxiliar Y160M-6 |

55 7.5 |

Preheater kiln |

| 11 | φ2.8×43m | 8.3 | 0.62-1.5 | 3 | Host ZS165-6 Auxiliar ZS50-1 |

Host YCT355-4B Auxiliar Y160L-6 |

75 11 |

Preheater kiln |

| 12 | φ2.8×55m | 6-7 | 0.62-1.5 | 3 | Host ZS165-6 Auxiliar ZS50-1 |

Host YCT355-4B Auxiliar Y160L-6 |

75 11 |

|

| 13 | φ3.0×48m | 700 | 0.67-3.76 | 3 | Host NZZL130-15-1 Auxiliar ZL50-10-2 |

Host ZSN4-280-091B Auxiliar YCT250-4A |

110 18.5 |

External decomposition kiln |

| 14 | φ3.0×50m | 9.2 | 0.5-1.5 | 3 | Host ZS165-3 Auxiliar ZS50-1 |

Host ZSN4-280-11B Auxiliar Y160L-6 |

125 11 |

Preheater kiln |

| 15 | φ3.0×60m | 7-9 | 0.5-1.5 | 4 | Host ZS165-3 Auxiliar ZS50-1 |

Host ZSN-280-11B Auxiliar Y160L-6 |

125 11 |

|

| 16 | φ3.2×48m | 1000 | 0.788-3.88 | 3 | Host NZS995-40VIBL Auxiliar NZS352-40IL |

Host ZSN-280-11B Auxiliar Y160L-6 |

125 11 |

External decomposition kiln |

| 17 | φ3.2×50m | 12.5 | 0.4-1.5 | 3 | 主 ZL130-16 Auxiliar ZL50-10 |

Host ZSN4-280-11B Auxiliar Y180L-4 |

125 22 |

Preheater kiln |

| 18 | φ3.2×50m | 1000 | 0.788-3.938 | 3 | Host NZS995-28VBR Auxiliar ZL50-9-2 |

Host ZSN4-280-21B Auxiliar Y180L-6 |

160 15 |

External decomposition kiln |

| 19 | φ3.2×64m | 8-10 | 0.4-1.5 | 4 | Host ZL130-16 Auxiliar ZL50-10 |

Host ZSN-280-11B Auxiliar Y180L-4 |

190 22 |

|

| 20 | φ3.3×50m | 1000 | 0.36-3.57 | 3 | Host NZS995-40-VBL Auxiliar NZS352-31.5 |

Host ZSN4-280-21B Auxiliar Y160M-4 |

160 11 |

External decomposition kiln |

| 21 | φ3.3×50m | 13 | 0.36-3.57 | 3 | Host ZSY450-40-VI Auxiliar ZL50-14-1 |

Host ZSN4-280-091B Auxiliar Y160M-4 |

160 11 |

Preheater kiln |

| 22 | φ3.3×52m | 1000 | 0.67-3.43 | 3 | Host NZS995-45VBL Auxiliar ZL50-10-1 |

Host ZSN4-280-21B Auxiliar Y160L-6(1100) |

160 11(15HP) |

External decomposition kiln |

| 23 | φ3.3×54m | 14 | 0.92-2.74 | 3 | Host NZS995-45VBL Auxiliar ZL42.5-10-2 |

Host ZSN4-280-11B Auxiliar Y160L-6 |

125 11 |

Preheater kiln |

| 24 | φ3.5×54m | 1500 | 0.55-3.5 | 3 | Host ZSY500-40-V Auxiliar ZSY180-31.5-2 |

Host ZSN4-315-092 Auxiliar Y200L-6 |

220 18.5 |

External decomposition kiln |

| 25 | φ3.5×130m | 22 | 0.439-1.379 | 5 | Host ZS165-3-1/2 Auxiliar ZL35-14-1/2 |

Host Z2-102 Auxiliar Y132S-4 |

2×90 2×5.5 |

Wet double drive |

| 26 | φ3.6×55m | 16.7 | 0.4-1.5 | 3 | Host ZSY500-40 Auxiliar ZSY180-31.5 |

Host ZSN-315-072 Auxiliar Y180L-4 |

250 22 |

Preheater kiln |

| 27 | φ3.8×58m | 20.8 | 0.4-1.5 | 3 | Host ZSY500-40 Auxiliar ZL50-14 |

Host ZSN-315-072 Auxiliar Y180L-4 |

250 22 |

Preheater kiln |

| 28 | φ4.0×60m | 25 | 0.4-1.5 | 3 | Host ZSY630-35.5 Auxiliar ZL65-16 |

Host ZSN4-355-092 Auxiliar Y200L-4 |

315 30 |

Preheater kiln |

| 29 | φ4.0×60m | 2000 | 0.58-3.459 | 3 | Host JH560-SW-56 Auxiliar ZL50-15 |

Host YTSP355-4 Auxiliar Y160L-4 |

250 15 |

External decomposition kiln |

Product Video

Key words:

Related Products

Related Products

Get Quote

Leave your contact information and get a free product quote