Product Classification

Cement ball mill is mainly used for grinding finished products and raw materials in cement plants. It is also suitable for grinding various ores and other grindable materials in metallurgy, chemical industry, power and other industrial and mining enterprises. It can be used for open flow grinding, and also for circulating flow grinding composed of powder concentrator. Cement mill has the characteristics of strong adaptability to materials, continuous production, large crushing ratio, easy speed adjustment and fineness of grinding products. Cement ball mill can produce by dry method or wet method, and can also grind and dry at the same time.

Learn more →Metallurgy, mineral processing ball mill

This machine consists of feeding part, discharging part, rotating part, transmission part (reducer, small transmission gear, motor, electronic control) and other main parts. The hollow shaft is made of cast steel, the inner part can be disassembled and replaced, the rotating large gear is processed by casting hobbing, and the cylinder is equipped with wear-resistant lining plate, which has good wear resistance. This machine runs smoothly and works reliably.

Learn more →Multi-channel burner,Industrial Gas Burner for Kiln

The rotary kiln multi-channel burner is a new type of burner that is gradually improved and developed on the basis of the four-channel burner. It is divided into four-channel single-fuel burner, five-channel single-fuel and double-fuel burner and six-channel single-fuel burner. The improved multi-channel burner has the following advantages:

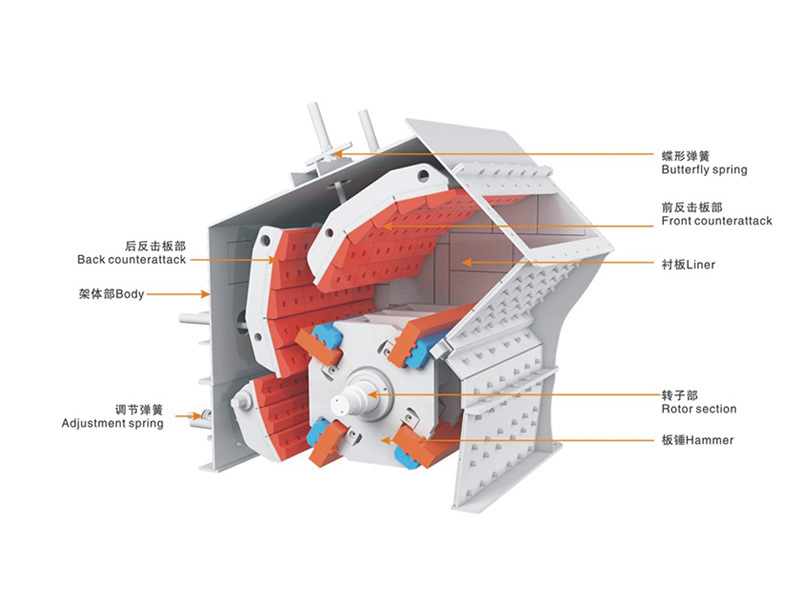

Learn more →This machine is suitable for fine crushing of medium hardness and brittle materials in industries such as mining, cement, coal, metallurgy, building materials, highways, and combustion. The high-speed rotating hammer collides with the material to crush the material. It has the characteristics of simple structure, large crushing ratio, high production efficiency, etc. It can be crushed in dry and wet forms. The equipment can adjust the grate gap according to user requirements and change the particle size of the material to meet the different needs of different users.

Learn more →This product can process various coarse, medium and fine materials (granite, limestone, concrete, etc.) with a side length not exceeding 500mm and a compressive strength not exceeding 350Mpa. It is widely used in ore crushing, railway, highway and construction industry artificial sand and gravel production. At present, the impact crusher is an irreplaceable equipment for high-grade sand and gravel crushing in practice. Structure, high chrome plate hammer, unique impact liner; hard rock crushing, high efficiency and energy saving; the product shape is cubic, the discharge particle size is adjustable, and the crushing process is simplified. After technical improvement, research and development, it can be equipped with new dust removal equipment to remove dust and benefit environmental protection.

Learn more →PE and PEX series jaw crushers are large compound swing type, widely used in many industries such as mining, smelting, construction, highway, railway, water conservancy and chemical industry to process various ores and rocks with large particle size and compressive strength not exceeding 320Mpa for coarse or medium crushing. PE series is used for coarse crushing, and PEX series is used for medium and fine crushing.

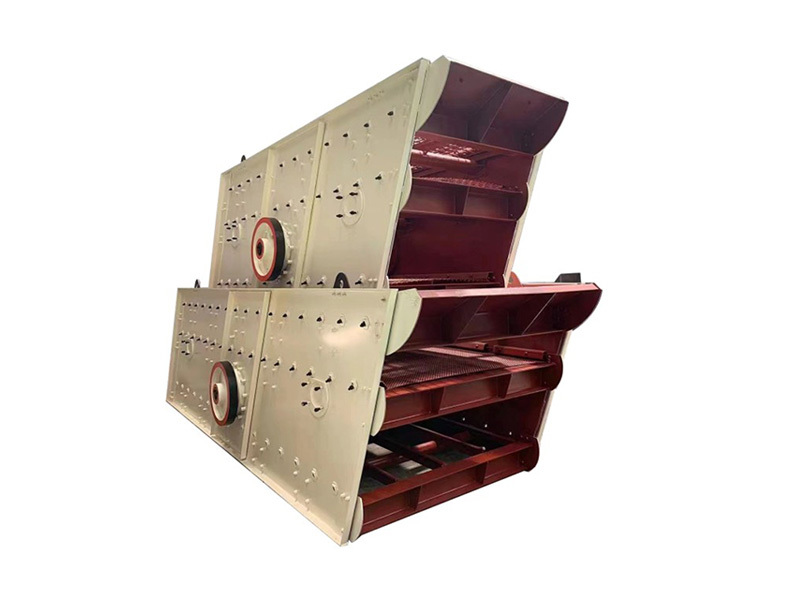

Learn more →The circular vibrating screen is called circular vibrating screen for short because its motion trajectory is similar to a circle. The circular vibrating screen is a new type of vibrating screen with multiple layers and high efficiency. The circular vibrating screen (circular vibrating screen) uses an eccentric block to adjust the amplitude, has a long material screening line, and has many screening specifications. The circular vibrating screen is widely used in product classification in mining, building materials, transportation, energy, chemical and other industries. It has the advantages of strong excitation force, simple structure, easy maintenance, stable operation, large processing capacity, long life, and low noise.

Learn more →The dust collector consists of a bracket, ash hopper, middle box, upper box, filter bag, frame, spray cleaning device and PLC control program. The middle box is a chamber structure. When working, the dust-containing gas is distributed to each ash hopper through the manifold. The coarser dust particles fall directly into the lower part of the ash hopper due to the reduction of wind speed and the collision of the baffles of each ash hopper. The fine dust rises with the air flow and disperses between the filter bags. The fine dust is retained on the outer surface of the bag. The clean gas passes through the bag with the negative pressure and enters the exhaust main pipe to be discharged from the machine body into the atmosphere, achieving the purpose of purification.

Learn more →Bucket elevator has the remarkable advantages of large conveying capacity, high lifting height, stable and reliable operation, and long service life. It adopts mixed or gravity unloading and digging loading. It is suitable for conveying low-abrasive materials in powder, material, and small blocks with a bulk density of less than 1.5t/m³ and easy to dig out, such as coal, cement, gravel, sand, fertilizer, grain, etc. The temperature of the conveyed material does not exceed 250℃.

Learn more →In the production process, the vibrating feeder can feed block and granular materials from the storage bin to the receiving device evenly, regularly and continuously. In the sand and gravel production line, it can feed the crushing machinery continuously and evenly and perform rough screening of the materials. It is widely used in the crushing and screening combined equipment in the metallurgy, coal mining, mineral processing, building materials, chemical industry, abrasive and other industries. It has the advantages of stable vibration, reliable operation, simple structure and dust prevention.

Learn more →The screw conveyor has the characteristics of compact structure, small cross-sectional area, light weight, good sealing performance, high conveying efficiency, flexible process layout, convenient installation, disassembly and movement, and safe operation. It is suitable for conveying various powdery, granular, and small-block bulk materials, such as clay powder, coal powder, cement, sand, grains, small pieces of coal, pebbles, and cast iron chips. It is not suitable for conveying materials with high viscosity, easy to agglomerate, and easy to deteriorate. The screw conveyor has two installation methods: horizontal and inclined. It can be used in conjunction with other conveying working devices to complete operations such as collection, distribution, stirring, mixing, dehydration, fixed batching, unloading, and stacking.

Learn more →