Pilot rotary kiln test | Iron ore powder calcination pilot test: Empowering scientific research and industry with technological strength

I. Dingxin Company: Deeply Cultivating Rotary Kiln Technology, Leading Industry Innovation

Henan Dingxin Equipment Technology Co., Ltd. (formerly Zhengzhou Yongxin Heavy Industry) located in Gaoshan Town, Xingyang City, Zhengzhou City, has focused on the research and development and manufacturing of rotary kiln equipment for more than ten years, mainly providing high-quality and efficient production equipment for the mining, building materials, metallurgy, and environmental protection industries. Main equipment includes rotary kilns, suspension flash calciners, ball mills, dryers, coolers, and lifting and conveying equipment. The company has a 20,000-square-meter modern processing workshop and a technical team with 30 years of industry experience, and has in-depth cooperation with Central South University Professor Li's team and Beijing Iron and Steel Research Institute Mr. Liu's team and other top scientific research institutions. Multiple patent technology breakthroughs have been achieved in the fields of tailings resource utilization and iron ore powder calcination.

In April 2025, the company completed the construction of a domestically leading pilot test kiln with "high efficiency and energy saving + intelligent control" as its core, providing process parameter verification, ratio optimization, and feasibility study services for scientific research units and enterprise customers, guaranteeing customer investment safety from the source and promoting the efficient transformation of technological achievements.

II. Advantages of the φ900*13.5m Pilot Test Rotary Kiln:

As a key transitional equipment between laboratory research and industrial production, the pilot test rotary kiln has many significant advantages, which can effectively improve the efficiency and reliability of technology transformation. The following is a detailed analysis of its main advantages:

1. Reduce Industrialization Risks

Risk Prevention: Before large-scale production, the feasibility of the process is verified through pilot tests, exposing equipment, process, or material problems (such as ring formation, insufficient thermal efficiency, poor corrosion resistance, etc.) in advance, avoiding high-cost failures in the industrialization stage.

Data-Supported Decision-Making: Through pilot test data (such as energy consumption, conversion rate, and exhaust emissions), the economic feasibility and environmental compliance are evaluated, providing a scientific basis for whether to proceed with mass production.

2. Flexibility and Adjustability

Precise Parameter Adjustment: Supports precise control of key parameters such as temperature, speed, inclination angle, and atmosphere (oxidation/reduction), facilitating the exploration of the optimal process window.

Multi-Scenario Adaptability: By changing the lining material, adjusting the sealing method, or changing the fuel type, it can adapt to different materials (such as high-viscosity sludge, metal ore powder) and reaction requirements (calcination, roasting, pyrolysis).

3. Significant Cost Effectiveness

Low Cost of Small-Scale Trial and Error: Compared to the huge investment in industrial kilns (tens of millions to hundreds of millions of yuan), the investment cost of pilot test equipment is lower (usually starting from hundreds of thousands of yuan), and the experimental energy consumption and raw material consumption are controllable.

Shortened R&D Cycle: Through rapid iterative testing (such as adjusting the calcination temperature curve or residence time), process optimization is accelerated, reducing the time from laboratory to mass production.

4. Data Acquisition and Analysis Capabilities

High-Precision Real-Time Monitoring: Integrated sensors and online analyzers (such as infrared thermal imaging, gas mass spectrometry) are used to obtain key data such as the temperature gradient inside the kiln, material conversion rate, and exhaust gas composition in real time.

Process Model Verification: Pilot test data can be used to correct laboratory models, improving the prediction accuracy of industrial-scale equipment (such as heat transfer simulation under scaling effects).

5. Comprehensive Technology Verification

Simulate Real Production Environment: Compared with static laboratory tests, the pilot test rotary kiln can simulate dynamic continuous production conditions (such as material rolling, heat field distribution, and mechanical stress), which is closer to actual operating conditions.

Equipment Reliability Testing: Verify the service life of lining materials, the stability of the sealing structure, and the durability of the transmission system, which are essential performance indicators for industrialization.

6. Support for Customization and Innovation

Process Innovation Testing: Provides a testing platform for cutting-edge fields such as new materials (such as precursors of lithium battery cathode materials), environmental protection technologies (hazardous waste co-processing), copper tailings, and gold tailings.

Customized Design: The kiln structure can be designed according to special needs (such as adding a preheating zone, multi-stage temperature control zone) or integrating auxiliary systems (such as waste heat recovery devices).

7. Environmental Protection and Safety Pre-assessment

Pollution Control Verification: Test the effectiveness of exhaust gas treatment systems (such as dust removal and desulfurization) and optimize emission indicators to meet environmental regulations.

Safety Risk Investigation: Identify safety hazards such as high temperature, high pressure, or harmful gas leaks in advance, and formulate safety protection measures for the industrialization stage.

8. Promote Technology Transformation and Commercialization

Attract Investment: Successful pilot test cases can provide intuitive proof of process maturity, enhancing investor confidence.

Establish Standards: Determine process control standards and operating procedures through pilot tests, providing clear guidance for industrial production.

Summary of Eight Advantages:

The core advantage of the pilot test rotary kiln lies in "simulating industrial conditions at a controllable cost to minimize technological risks and maximize process benefits." It is the "necessary bridge" for technology to go from the laboratory to the market, and its value is even more prominent in rapidly iterating fields such as new materials, new energy, and environmental protection.

III. Customer Case: Full Process of Iron Ore Powder Calcination to Improve Grade

1. Proportioning and Feeding

After drying and screening, the iron ore powder is fed at a constant speed through a high-precision weighing sensor (error <1%), ensuring the stability of the starting point of the experiment.

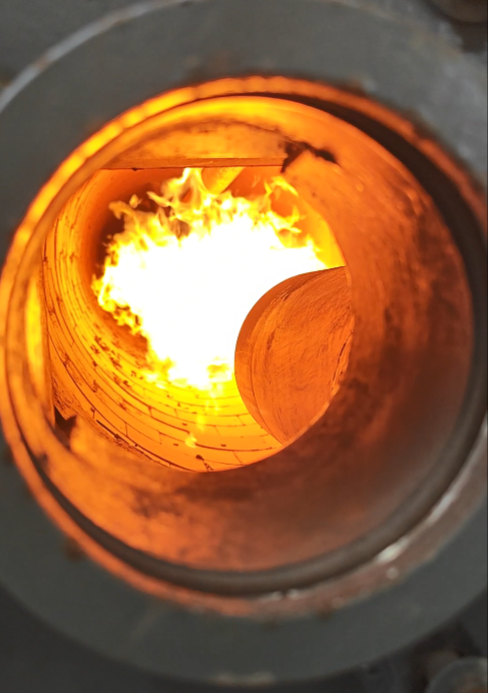

2. Calcination Process

Preheating zone (200-400℃): Remove residual moisture and prevent agglomeration.

High-temperature zone (1200℃): Intelligent control of oxidizing/reducing atmosphere, precise control of material residence time

3. Discharge and detection: The calcined product is rapidly cooled with cold water, discharged through a closed airlock valve to avoid secondary oxidation; after the waste gas is treated to meet the standards, it is discharged, and the product composition is detected online to immediately verify the process effect.

4. Results: The customer successfully obtained the optimal calcination parameters, providing key data support for the subsequent design of a 10,000-ton-level production line.

IV. Invitation to cooperate: Strong Test support to promote technological upgrades

Whether you are a research institution verifying new processes, or an investor in the new materials, metallurgy, chemical, environmental protection, and solid waste industries, Dingxin Equipment Pilot test kilns can provide you with:

Test support: Incoming material calcination test + data analysis, reducing early investment risks.

Customized solutions: Calcination parameters are tailored to the characteristics of the materials, covering different raw materials and ratio requirements.

Full technical support: From experimental design to industrial production, a senior team provides full support.

Previous

Recommend Content

Understanding the Role of Metallurgy Ball Mills in Material Processing