Products

Hot Products

Various models, according to your needs to customize the production program

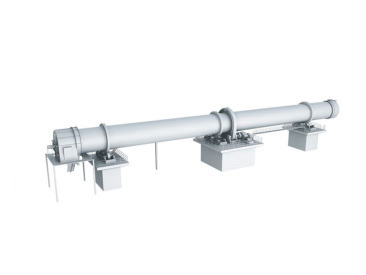

The rotary kiln is composed of cylinder body, transmission device, supporting device, supporting device, kiln lining, kiln tail seal, kiln head cover and fuel device.

Case

Company Case

Live shooting, promote the development of the world industry

Northeast Lime Rotary Kiln Production Line

Capacity:

150~300TPD

Handling material:

Calcium carbonate stone

Korean lime rotary kiln production line

Capacity:

150~300TPD

Handling material:

Calcium carbonate stone

Sichuan cement rotary kiln production line

Capacity:

200~300TPD

Handling material:

Cement raw materials

Northeast Lime Rotary Kiln Production Line

Capacity:

150~300TPD

Handling material:

Calcium carbonate stone

Korean lime rotary kiln production line

Capacity:

150~300TPD

Handling material:

Calcium carbonate stone

Sichuan cement rotary kiln production line

Capacity:

200~300TPD

Handling material:

Cement raw materials

Northeast Lime Rotary Kiln Production Line

Capacity:

150~300TPD

Handling material:

Calcium carbonate stone

Korean lime rotary kiln production line

Capacity:

150~300TPD

Handling material:

Calcium carbonate stone

Sichuan cement rotary kiln production line

Capacity:

200~300TPD

Handling material:

Cement raw materials

Northeast Lime Rotary Kiln Production Line

Capacity:

150~300TPD

Handling material:

Calcium carbonate stone

Korean lime rotary kiln production line

Capacity:

150~300TPD

Handling material:

Calcium carbonate stone

Sichuan cement rotary kiln production line

Capacity:

200~300TPD

Handling material:

Cement raw materials

About Us

Committed to creating an international business card

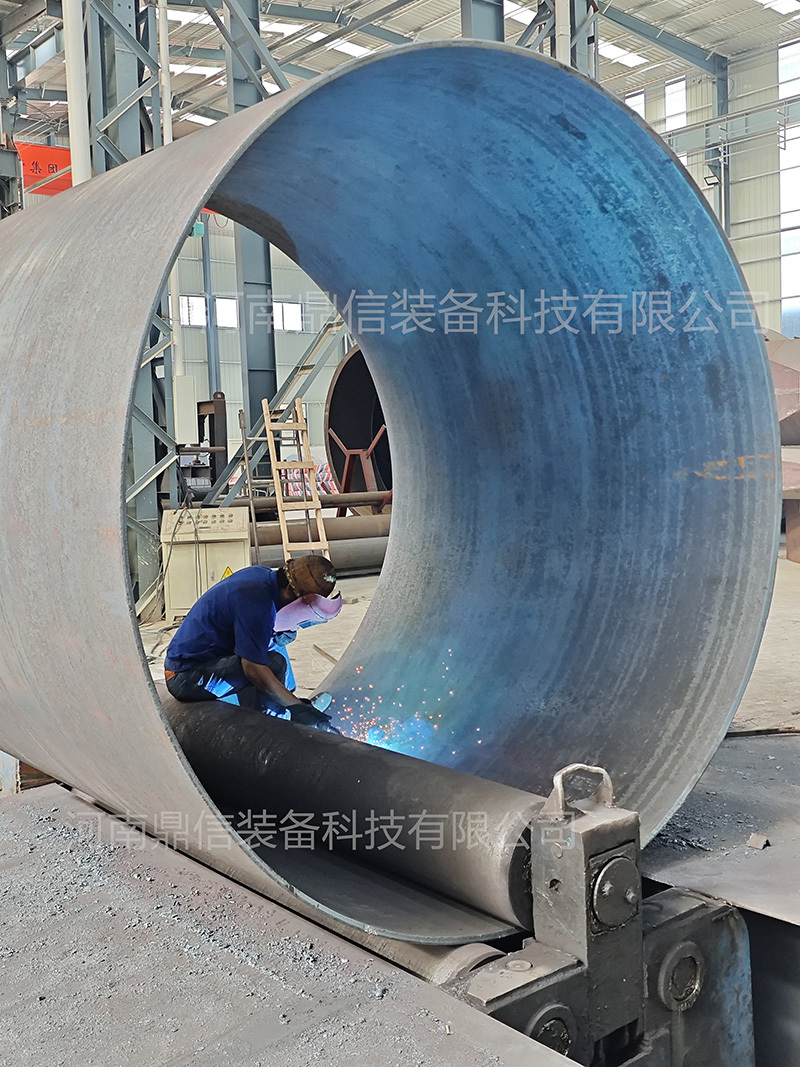

Henan Dingxin Equipment Company is a comprehensive modern enterprise integrating process design, equipment selection, equipment manufacturing, sales, installation and commissioning and training services. Dingxin Company has excellent technical team, installation team and after-sales team, which can undertake the design planning, equipment manufacturing, installation and commissioning of new factories, as well as personnel training and after-sales service.

The company's main products are lime rotary kiln, reducing iron rotary kiln, ceramsite rotary kiln, waste incineration rotary kiln, sludge incineration rotary kiln, bauxite rotary kiln, water purification agent rotary kiln, alumina rotary kiln, magnesium oxide rotary kiln, zinc oxide rotary kiln, carbon rotary kiln, calcium aluminate rotary kiln, shale rotary kiln and so on.

Plant area

Technical staff

Country/Country

The company has rich experience in production, engineering construction and installation services.

Quality Assurance

We uphold the values of technological innovation, scientific management, and are keen to adopt advanced production equipment.

Partners

Sales Area

Factory

Factory Display

Covering an area of 14000 ㎡, it is located in Gaoshan Town, Xingyang City, Zhengzhou City.

Customer Visits

Welcome friends from all over the world to visit

News

Company News

Pay attention to Dingxin dynamic, understand the development of the industry